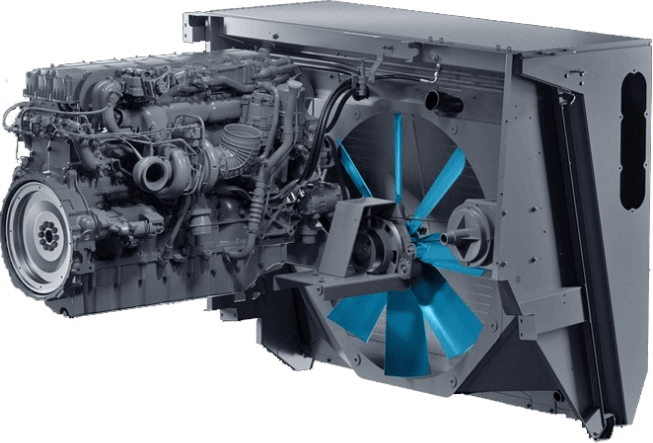

How It Works

The fast-pitch action of the Flexxaire reversing fan blows out the debris that can clog your radiator, without changing the fan rotation or orientation.

Learn MoreComponents

The Flexxaire fan system includes reversible fan blades designed to operate in extreme conditions, an adjustable variable pitch engine cooling hub, and feature-rich controls that work together to ensure optimum engine performance.

Learn MoreBrands & Machines

As a global supplier of reversing radiator fans for a wide range of off-road applications, Flexxaire is a trusted partner for many of today’s leading machinery brands and aftermarket suppliers.

Learn MoreSEE WHY OUR REVERSIBLE FAN LEADS THE WAY

When it comes to understanding the superiority of the Flexxaire reversible fan system, seeing is believing. View our video for the full story.

JOIN THE LEADERS THAT RELY ON FLEXXAIRE

WHAT OUR CUSTOMERS ARE SAYING

LET’S TALK ABOUT YOUR NEEDS

To learn more about Flexxaire reversible radiator fan systems—or for help in pinpointing the fan that meets your needs, please reach out to us.